Ortner Reinraumtechnik

Specialist for cleanroom solutions

Powerful imagery for cleanroom technology.

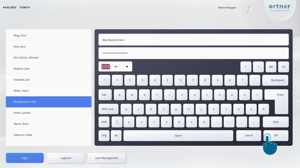

UX/UI Design, Software

The Austrian company specializes in cleanroom technologies. They develop solutions such as transfer systems, isolators, laminar flow systems, and decontamination units, particularly for pharmaceuticals, biotechnology, and electronics.

Development of a new operating concept as part of a system change in the hardware area.

.jpeg?width=640&height=397&name=Mittel%20(HMI_Ortner_Alphagate).jpeg)

Project description

Ortner Cleanroom Technology requires a user-friendly HMI that securely and intuitively represents processes in the fields of pharmaceuticals, medicine, and biotechnology. The goal was to develop a unified operating concept that covers all machines and optimally supports operators.

Project Goals:

- User-Centered: Intuitive navigation, clear visualization of process steps, alerts, and errors.

- Standardization: Unified HMI for all Ortner machines, modular and flexible.

- Safety: Support for cleanroom standards and tamper-proof data logging.

Alphagate’s Contribution:

- Design and development of a moderne HMI.

- Support in integrating a newly designed PLC.

- Validation of user-friendliness and process safety.

Results:

The new HMI improves user-friendliness, reduces errors, and creates a future-proof foundation for all Ortner machines.

Challenges

Complex cleanroom processes require clear and intuitive visualization to optimally support operators in every situation.

Minimization of operator errors through understandable navigation and the display of critical information.

Development of a unified HMI concept that is flexible and applicable to all Ortner machines.

Ensuring modularity to enable industry-specific customizations.

Adaptation of the HMI to a newly designed PLC, which was not developed by Alphagate but had to be taken into account for seamless integration.

Close coordination between teams to correctly implement all interfaces and functions.

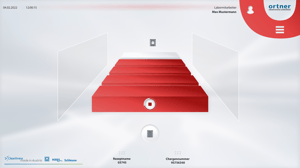

Visualization of the current process status and relevant notifications in real-time.

Tamper-proof data logging to meet strict cleanroom standards.

Consideration of the specific requirements of cleanroom technology, such as high safety standards and precise monitoring.

Development of an operating concept that meets both technical and regulatory requirements.

–Wolfram Kofler, Head of R&D

Results

.png?width=300&name=UC%20-%20Prozess%20Starten%2006%20(1).png)

Subscribe to our newsletter & never miss a thing!

Receive regular news, updates, and special offers straight to your inbox.