Line Management

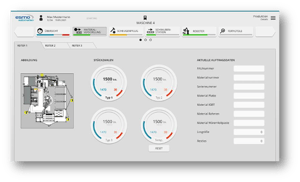

Working in production lines and cells can become very complex. With A-Line from Alphagate, you can control and monitor machines within a line.

What is Line Management

Line Management in industrial production optimizes and coordinates complex processes, ensuring smooth operations, especially in industries with high standards like automotive and pharmaceuticals. It involves managing multiple machines, often with different HMI systems, and consolidating critical information for centralized monitoring. By selectively displaying user-specific data, it enhances efficiency and enables quicker responses to issues, helping streamline production while maintaining quality and safety.

Why Line Management for the mechanical engineering industry

Focus on what matters

Process-relevant information, such as recipes, messages, and progress, is summarized from different machines.

Heterogeneous data

Data from different systems are consolidated and presented in a structured way for A-Line.

Display machine status

- Operating status: In operation, downtime, or maintenance.

- Error messages: Current or past disruptions.

- Production speed: Units per time.

- Temperature and pressure: Critical parameter monitoring.

- Energy consumption: Current energy usage.

- Maintenance status: Planned or required maintenance.

- Material status: Availability and consumption of materials.

- Quality data: Quality of produced units.

Line recipes

Subscribe to our newsletter & never miss a thing!

Receive regular news, updates, and special offers straight to your inbox.