Esmo

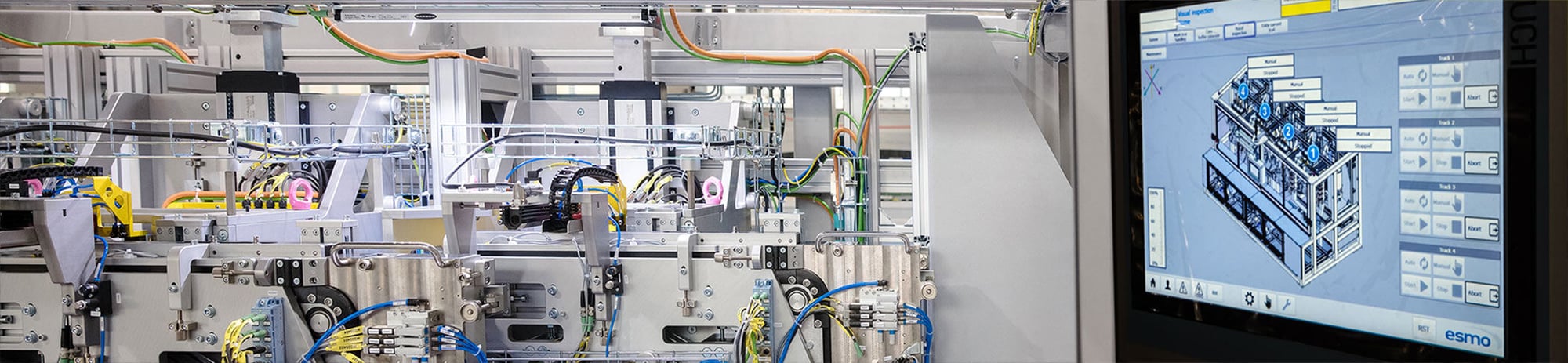

Custom machine construction for highly complex processes in industry.

Development of an operating concept and corresponding HMI software that enables the implementation of highly flexible solutions in custom machine construction.

UX/UI Design, Software

ESMO Automation develops machines for renowned clients (Siemens, Bayer, etc.) tailored precisely to their specific needs.

At the beginning of a project, the requirements for an HMI are often not yet clear. The goal is to achieve the greatest possible flexibility with the new solution, regardless of the desired process and the hardware used (robotics, PLC, etc.).

Project description

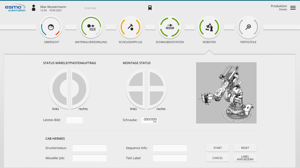

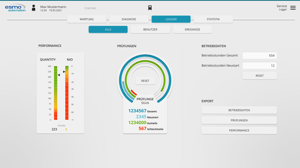

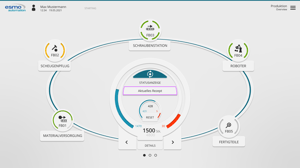

Our goal with the esmo CORE (based on A-Sphere and A-Vis) is to develop a central control solution for all automation systems. The esmo CORE is intended to serve as the control core, central hub, remote maintenance module, and safety system, enabling seamless integration through standards like PackML and OPC UA.

We focus on an intuitive graphical user interface (HMI) so that users can operate the machine independently after a brief introduction, without the need for programming knowledge. This ensures that the operation of our machines is simple and efficient.

With the esmo CORE, we also aim for consistently high quality, easy maintenance, and long-term upgradability of the machines to make them future-proof for new ecological and digital challenges.

Challenges

Modularity

The system must be flexible and expandable to support different machine configurations.

Integration

Compatibility with existing machines and control systems through standards like OPC UA must be ensured.

Safety

Stringent safety requirements must be met to protect both people and machines.

User-friendliness

The HMI must be intuitive to operate, even without technical prior knowledge.

Sustainability

The system must be upgradable and adaptable to future requirements.

–Michael Grampp, Product Development Software

Results

Subscribe to our newsletter & never miss a thing!

Receive regular news, updates, and special offers straight to your inbox.